Other Commercial Services

United Structural Systems is proud to offer a variety of commercial concrete repair services to our clients in and around Charleston, Lexington, and Cincinnati.

Pressure Grouting

Also known as mudjacking or slab jacking, pressure grouting is a common form of concrete slab repair where small holes are drilled into the concrete slab, then grout is pumped into the soft or weak soil layers or void and lifts the concrete back into place by stabilizing and strengthening the soil that exists within the void. Pressure grouting controls the amount of grout going into the pipe so it can be done with precision. Our team in Charleston and Lexington first pump the grout down into the lowest elevation of the void and withdraw the pipes slightly, allowing the grout to set. The process is then repeated at the next elevation and so on until the surface is reached. The grouting works with the soil beneath the concrete to create a compact, stable base for the concrete above. Pressure grouting for your Charleston or Lexington business is a great option for commercial concrete slab repair because it keeps you from having to dig up anything, which can be a costly project with a lot of downtime for your concrete. You get to pinpoint the areas that need attention and don’t have to worry about cleaning away excess dirt or concrete.

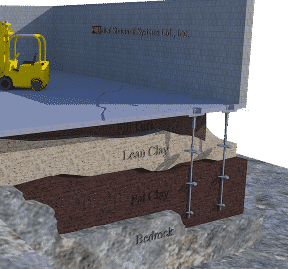

Helical Slab Repair Brackets

Our specialists in Charleston and Lexington use another form of concrete repair is the use of helical slab repair brackets, which are large steel piers that dig deep down into the soil to stabilize the surface. This method is more common in commercial or industrial slabs with heavy traffic or heavy machinery loads, and is also used when pressure grouting has failed due to continuing subsidence. Helical slab brackets give reliable support and are easy to install - they’re also engineered to provide many years of service once they’re put in place. They are installed on top of helical anchors to add strength. They can be mechanically or hydraulically used to lift settling slabs. This is an economical approach to adding support to concrete that sees a lot of heavy loads.

Retrofit Brick Ties

These ties are designed to reinforce the brick walls of flooded buildings. A small hole is drilled into the brick wall and filled with mortar and epoxy. They are installed from the interior walls and anchored to the stud framing with screws. First our team in Charleston and Lexington go in and remove any mortar squeezings from the interior of the wall and then drill in to install the retrofit brick tie. While originally designed for flooded homes where sheathing and brick ties had to be removed, retrofit brick ties can be used in any interior side renovation of masonry walls. They can stabilize bowing and/or bulging walls by securing them to the stud framing. Don’t jump right to the conclusion that you have to tear down your brick wall if you notice this type of damage, let USS assess whether or not we can utilize these retrofit ties to stabilize your masonry.

Foam Injection Concrete Leveling

High Density Polyurethane Foam Injection Leveling can help stabilization by filling voids below the concrete slab. The foam will not lose its density after curing and will maintain its compressive strength. This product can also be applied in a manner that can stiffen the soil directly below the affected area of installation. The polymer foam we use is a closed-cell polymer, which means the gas pockets are sealed from each other, preventing water from being soaked up. The foam is injected as a liquid and, as it expands, it travels the path of least resistance which leads it to find the low spots and expand in all directions. In just about six seconds the expansion begins, first expanding into weak soils to compact it and create a more dense foundation for your concrete slab. In about 15 seconds the foam will be completely expanded.

Foam Injection vs. Pressure Grouting

While the method of pressure grouting is similar to foam injection, there are important differences to consider when you’re contemplating one or the other for your concrete slab repair. One of the most significant differences is the amount of cure time that is needed for the two different materials. The grouting material is generally a dense, finely-crushed limestone aggregate (often mixed with Portland cement) combined with water in a slurry consistency that is pumped through holes that are about 1 inch in diameter. This material requires a lengthy cure period before you can use the area. The polyurethane foam, on the other hand, is injected through a hole about the size of a dime and cures after just 15 minutes. You can drive a car over the repaired area in as little as a half an hour.

Call Us Today!

Contact us today for free estimates! We have commercial concrete repair service areas in Charleston, Cincinnati, Lancaster, Lexington, and Cross Lanes!